Land resource conservation: Availability on water reservoir, fishpond, mining subsidence area, coastal waters etc.

Water protection: reduce water evaporation, control algae growth

Power generation improvement: good water-cooling effects, 10% more power generation

Convenient O&M: no obstructions, convenient cleaning

Easy installation: short period installation cycle

Market Advantages: abundant water resource and able for large-scale promotion

·Suitable for producing 500 -1000L different size solar floating FPV products:

Solar Panel Floats HDPE pontoons Buoys

Solar Floater / PV floating units / photovoltaic floater units / Solar Pontoo

floating solar panels/solar floating/floatovoltaics/floating solar pv/floating photovoltaics/floating pv system

floating solar system/floating photovoltaic system/pv floating/oceanographic buoy

FLOATING PV SYSTEM/floating platform/Floating photovoltaic power station

Water Floating Solar Power Plant/Floating solar power plants/floating photovoltaic (FPV)

·Optional bottom sealing,product eject,core-pulling movement ele

·Adopt high output extrusion system,accumulating die head.

·According to the different product size, customized the platen type and size.

·Hydraulic Servo control system.

·Optional double layer co-extrusion system.

·Adopt high output extrusion system,accumulating typedie head,hydraulic servo control system

| Model | Unit | BM1000 |

| Max product volume | L | 1000 |

| Dry cycle | Pc/h | 155 |

| Die head structure | Accumulating type | |

| Main screw diameter | mm | 120*2 |

| Max plasticizing capacity(PE) | kg/h | 700 |

| Driving motor | Kw | 132*2 |

| Accumulating volume | L | 75/90 |

| Oil pump motor power | Kw | 55 |

| Claming force | KN | 1800 |

| Max space between platen | mm | 1000-2700 |

| Platen size W*H | mm | 1900*2300 |

| Max moild size | mm | 1750*2200 |

| Heating power of die head | Kw | 65 |

| Machine dimension L*W*H | m | 14*12*8.5 |

| Machine weight | T | 70 |

| Total power | Kw | 460 |

Parison Control System

We adopt MOOG 100 point parison control system, it can ensure products weight and thickness perfectly

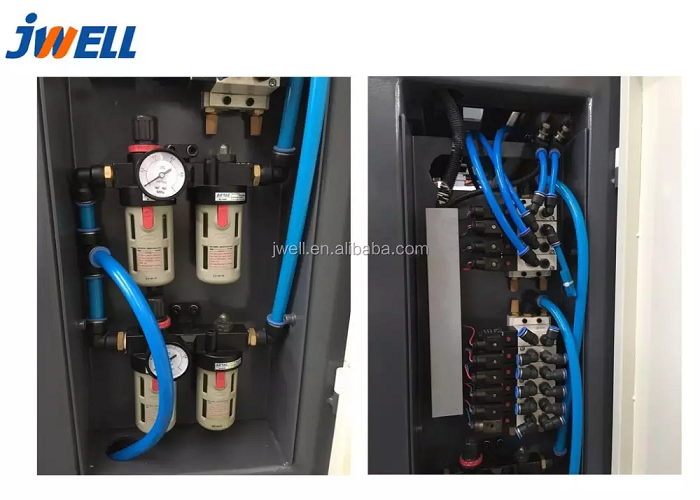

Pneumatic Control System

Pneumatic circuit just uses special blowing technique, and the pressure and flux of compressed air is even.

The pneumatic valves are Chinese famous brand—Air TAC

Hydraulic Control System

Hydraulic control system uses servo-control technology to control the movements of actuators, so it has advantages as follows: quick response and energy-saving feature.

Contact: Lily Xu

Phone: +86 15806225887

Tel: +86-0512-53660809

Email: infssx@jwell.cn

Add: No 18, Dongan Road, Taicang, Suzhou city, Jiangsu Province, China, 215400

We chat